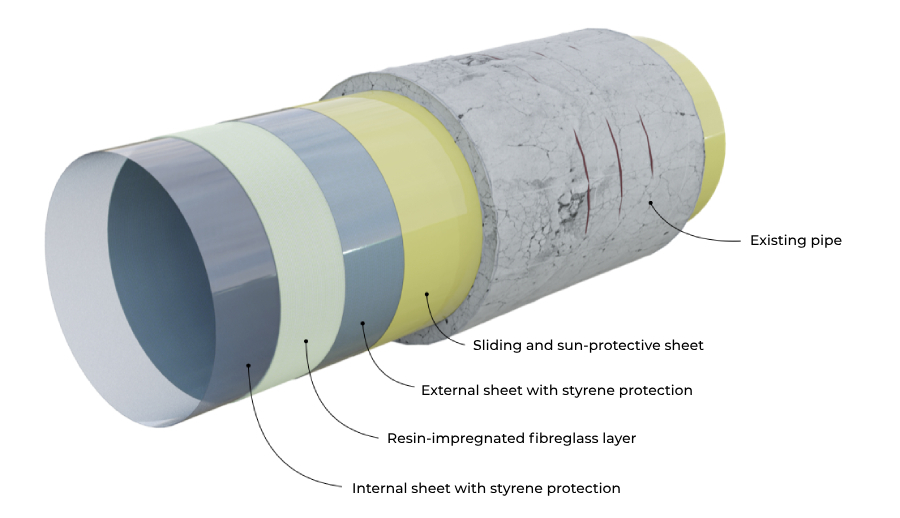

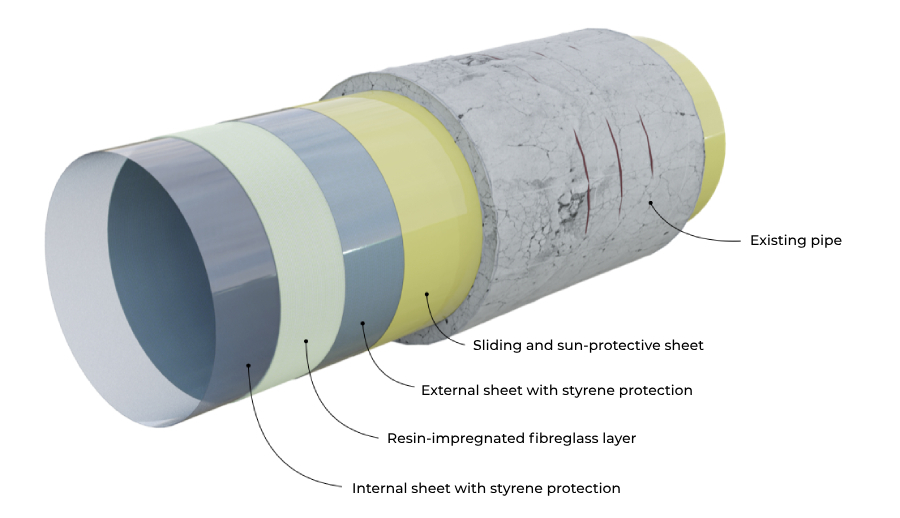

Liner Structure

Rusliner-Tech is the first Russian manufacturer of UV-cured fiberglass pipe liner for trenchless pipe rehabilitation.

We produce liners for restoring pressure and gravity sewers, oil, gas, and fuel pipelines, as well as UV-cured fiberglass pipe liners for trenchless rehabilitation of potable water pipes.

| Gravity Pipeline Liner | Pressure Pipeline Liner | |

| Diameters | 150-1600 mm (step changes possible) | 200-1200 mm (step changes possible) |

| Wall thickness | 3-15 mm | 4.3-14.3 mm |

| Cross-sections | Circular, oval, egg-shaped, and box-shaped profiles | Circular cross-sections |

| Bends | Up to 30 degrees | Up to 10 degrees |

| Curing | Ultraviolet | |

| Application area | Sewer, stormwater, and industrial drainage systems | Pressure sewer, stormwater, oil, fuel, gas pipelines |

| Short-term modulus of elasticity | 20500 N/mm2 | |

| Short-term flexural strength | 270 N/mm2 | |

| Maximum pipe section to be rehabilitated | up to 300 m | |

The fiberglass liner has high resistance to corrosion and abrasion.

It can be used in any pipe cross-section: circular, oval, egg-shaped, or box-shaped profiles.

By reducing the roughness of the material on the inner surface, it increases the flow rate.

Trenchless pipe rehabilitation using UV-cured fiberglass liners enables quick and excavation-free restoration, which can be completed in just 4 hours.

This technology is not only 30% cheaper than traditional repair methods, but it also helps avoid the challenges of dismantling work and enables the restoration of pipes that cannot be replaced using open-cut methods.

Rusliner-Tech

Yesipovo Industrial Park, Bld 8

Solnechnogorsk Urban District, Moscow Region